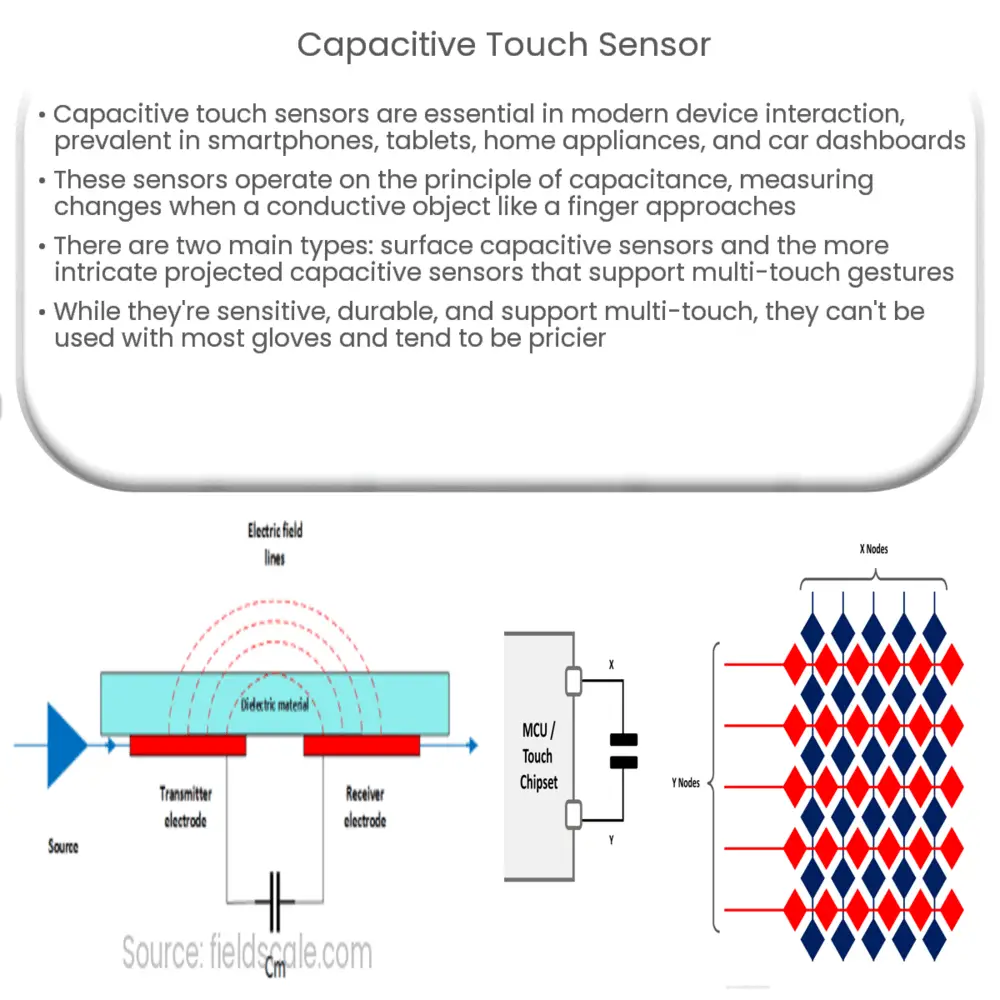

Capacitive touch sensors have revolutionized the way we interact with technology, offering seamless, touch-sensitive interfaces that are highly responsive. These sensors, often used in DIY projects, can be easily integrated into various applications, including 3D printed objects. By utilizing conductive materials like copper tape, hobbyists can embed sensors in 3D prints, creating intuitive touch buttons that enhance usability. As pioneers like John Phillips demonstrate, with the right techniques, you can create engaging interfaces that blend technology with creativity. Additionally, employing an Arduino capacitive touch library can simplify the programming process, allowing you to bring your innovative projects to life with ease.

Touch-sensitive technology, known for its intuitive interaction, is increasingly being embedded in creative projects. Enthusiasts and makers often refer to these as interactive sensors that respond to bodily capacitance, fostering innovation across numerous fields. Many DIY enthusiasts leverage Arduino platforms to enhance their projects, particularly in combination with flexible materials like copper tape. The integration of such sensors into 3D prints not only aesthetics but also functionality, transforming ordinary objects into smart devices. Whether you’re exploring the world of 3D printing touch buttons or designing intricate capacitive touch systems, the possibilities are expansive and exciting.

Integrating Capacitive Touch Sensors into DIY 3D Prints

Capacitive touch sensors are revolutionizing the way DIY enthusiasts approach their 3D printing projects. By integrating these sensors directly into the designs, creators can eliminate the need for bulky external buttons or switches. The process is simple yet innovative, requiring just a conductive material like copper tape and a microcontroller. As explained by John Phillips in his latest DIY project, this method allows for seamless interaction with the printed object, making it not only user-friendly but also aesthetically pleasing.

When embedding these sensors, precision becomes paramount. Ideally, one should pause the 3D print at a designated level to insert the sensors, keeping them well-protected beneath subsequent layers. By placing the copper tape three layers deep, as John suggests, the conductive surface is shielded adequately, preventing exposure to external elements. The benefits of this technique are multifaceted, providing both functional touch capabilities and maintaining the structural integrity of the 3D print.

Frequently Asked Questions

What are capacitive touch sensors and how are they used in DIY projects?

Capacitive touch sensors are devices that detect touch through the capacitance change when a finger is near. They are popular in DIY projects because they allow for the creation of touch-based interfaces with minimal components. By using conductive materials, such as copper tape, you can create touch buttons that can be easily integrated into various projects, including those utilizing Arduino.

How can I integrate capacitive touch sensors in 3D printing projects?

Integrating capacitive touch sensors in 3D printing can be accomplished by embedding conductive materials like copper tape into the print. This is done by pausing the print at a suitable layer height to place the copper tape, which acts as the touch sensor, and then continuing the print. John Phillips recommends positioning the tape about three layers deep for optimal functionality.

What materials are recommended for creating DIY capacitive touch buttons?

For DIY capacitive touch buttons, copper tape is highly recommended due to its excellent conductivity and adhesive properties. It can be easily soldered and embedded into your 3D prints, making it an ideal choice for creating touch-sensitive interfaces.

How do you create 3D printing touch buttons using Arduino?

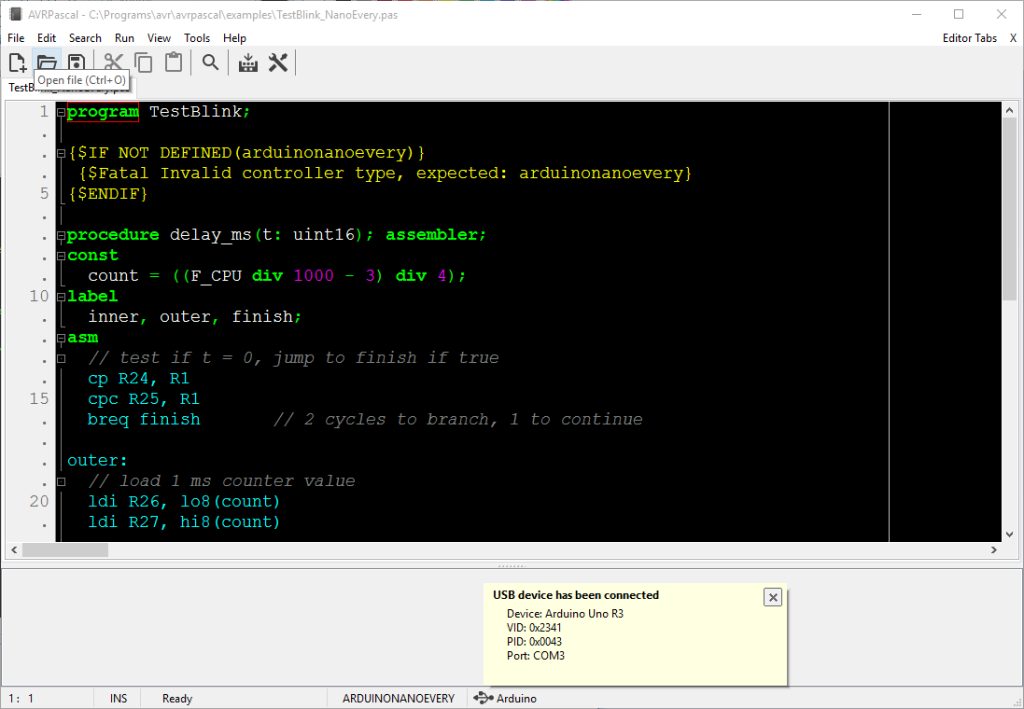

To create 3D printing touch buttons using Arduino, you need to integrate capacitive touch sensors like copper tape into your printed designs. After embedding the tape into your 3D model, you can use Arduino libraries to interpret the touch signals. Custom codes can be developed for more complex functionalities, as demonstrated by John, who created his own coding solution for better control.

Can you explain the process of embedding capacitive touch sensors in a 3D print?

The process of embedding capacitive touch sensors in a 3D print involves pausing the print at a designated layer height, placing conductive materials such as copper tape, and then resuming printing. It’s crucial to place the tape a few layers down into the print—about three layers is optimal—so that it is well-protected yet still functional.

What are some common issues when using capacitive touch sensors in DIY projects?

Common issues with capacitive touch sensors in DIY projects include interference from surrounding electronic components and the need for proper embedding techniques. Ensuring that the copper tape is securely soldered and positioned under the right layer thickness can help mitigate these issues, as John Phillips highlights in his recommendations.

How do I solder wires to copper tape used in capacitive touch sensors?

To solder wires to copper tape used in capacitive touch sensors, first, allow a small hole above the taped area during printing. After completing the print, you can insert a wire into this hole and secure it with a soldering iron and solder. This technique ensures that the connection is strong and reliable.

What software can I use for programming Arduino with capacitive touch sensors?

For programming Arduino with capacitive touch sensors, you can utilize existing libraries specifically designed for capacitive sensing. However, if you want more control, consider developing your own code, as John Phillips did, which can enhance the functionality of your touch sensors in DIY applications.

What is the best way to ensure a reliable capacitive touch sensor in a 3D printed object?

To ensure a reliable capacitive touch sensor in a 3D printed object, position the copper tape three layers deep from the surface and ensure it’s securely soldered to avoid connectivity issues. Additionally, use an Arduino library for touch sensing to maintain accuracy in touch detection, and consider environmental factors that might affect capacitance.

Can a simple spring work as a capacitive touch sensor?

Yes, a simple spring can function as a capacitive touch sensor by making direct contact with the conductive material. This method offers an alternative to traditional touch sensors and can be incorporated into designs where an embedded solution is not feasible.

| Key Points |

|---|

| Capacitive touch sensors are ideal for DIY projects, requiring a conductive surface and a microcontroller. |

| Integration of touch buttons into 3D prints enhances functionality without additional hardware. |

| Embedding capacitive touch sensors requires pausing the 3D print at the right moment to insert hardware. |

| Using copper tape as a touch pad is effective; it should be placed three layers in for optimal sensitivity. |

| A small hole above the copper tape allows for easy soldering of wires post-printing. |

| Arduino libraries simplify coding for capacitive touch sensors, but custom solutions can enhance the project. |

| Alternative methods like using springs are also effective for achieving capacitive touch sensing. |

Summary

Capacitive touch sensors represent a valuable addition to DIY projects, offering an innovative and practical solution for integrating touch functionality into 3D printed designs. By utilizing conductive materials like copper tape and strategically embedding them during the printing process, makers can create custom touch interfaces that are both effective and efficient. The integration of Arduino libraries further empowers users to develop bespoke solutions, ensuring that capacitive touch sensors become a seamless part of their projects.